Boulder Strip Stone Processing and Production Line

Key words:

Boulder strip stone processing and production line

Boulder Strip Stone Processing and Production Line

Classification:

Product Description

Equipment introduction

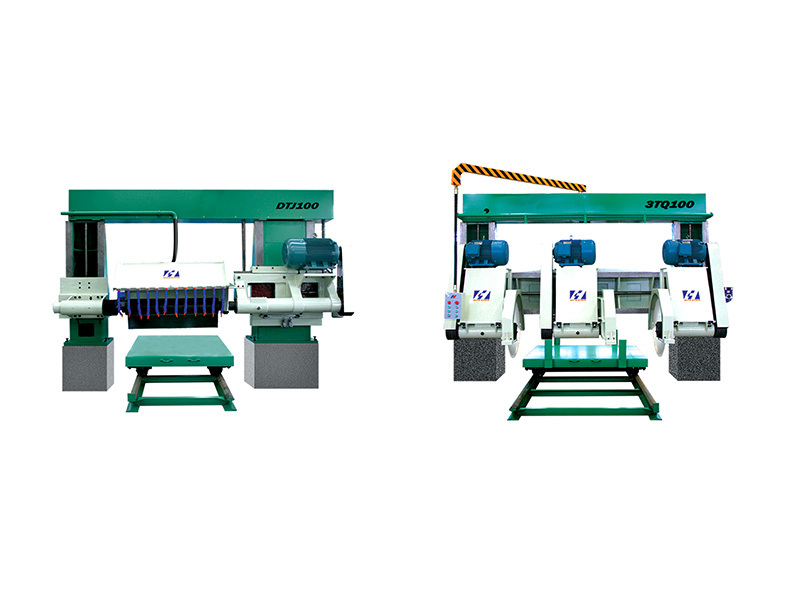

DTJ120 Bar Stone Processing and Production Line is the professional equipment for processing roadside stone, tombstone, stone for paving square, platform, etc. If using it with three pieces blade machine, the Bar Stone Processing and Production Line will be made up, and the efficiency will be improved.

The features of this machine are as following:

Because of the assistance support be used in the fore-end main shaft, and the main shaft revolves smoothly,

Operation easy, in the movement of main shaft the request of stone position is not high.

It is easy to exchange the blade.

The control section adopts manual and semi-automatic control, and the working table adopts stepless speed regulation.

The using range is wide, and be used for cutting the bar stone which the width is less than 1000mm.

Technical parameter

1. Maximum number of disc: 6 pieces

2. Maximum diameter of disc: Φ1200mm

3. Maximum vertical stroke: 600mm

4. Working table feeding stroke: 2500mm

5. Moving left right stroke: 300mm

6. the working table surface area: 1700*1200mm

7. Disc elevator speed: 525mm/min

8. Maximum working table feeding speed: 5920mm/min

9. Total capacity: 40.75KW

a. main motor: 37 KW

b. vertical motor: 1.5 KW

c. moving left right motor: 0.75KW

d. working table motor: 1.5KW

10. Overall dimension: 7000(W)*3800(L)*2800mm(H)

11. Weight: 6000Kg

- 产品描述

-

- Commodity name: Boulder Strip Stone Processing and Production Line

DTJ120 Bar Stone Processing and Production Line is the professional equipment for processing roadside stone, tombstone, stone for paving square, platform, etc. If using it with three pieces blade machine, the Bar Stone Processing and Production Line will be made up, and the efficiency will be improved.

Equipment introduction

DTJ120 Bar Stone Processing and Production Line is the professional equipment for processing roadside stone, tombstone, stone for paving square, platform, etc. If using it with three pieces blade machine, the Bar Stone Processing and Production Line will be made up, and the efficiency will be improved.

The features of this machine are as following:

Because of the assistance support be used in the fore-end main shaft, and the main shaft revolves smoothly,

Operation easy, in the movement of main shaft the request of stone position is not high.

It is easy to exchange the blade.

The control section adopts manual and semi-automatic control, and the working table adopts stepless speed regulation.

The using range is wide, and be used for cutting the bar stone which the width is less than 1000mm.

Technical parameter

1. Maximum number of disc: 6 pieces

2. Maximum diameter of disc: Φ1200mm

3. Maximum vertical stroke: 600mm

4. Working table feeding stroke: 2500mm

5. Moving left right stroke: 300mm

6. the working table surface area: 1700*1200mm

7. Disc elevator speed: 525mm/min

8. Maximum working table feeding speed: 5920mm/min

9. Total capacity: 40.75KW

a. main motor: 37 KW

b. vertical motor: 1.5 KW

c. moving left right motor: 0.75KW

d. working table motor: 1.5KW

10. Overall dimension: 7000(W)*3800(L)*2800mm(H)

11. Weight: 6000Kg

Product Video

DTJ100+3TQ100 1G

Production Equipment

Container shipments

Communication and exchange

FAQ

I need a stone cutting machine , can you give me some suggestions?

Sure, we will give suggestions of the most suitable machine and total solution of whole factory . Before that, we need to know some information, such as stone type, capacity, site condition ,etc., to determine the main parameters.

Which kind of materials can be processed on this machine?

marble B:Granite

Are you a factory or trading company?

We are the manufacturer and we have 10 years factory experience, As the machine made by JUXING factory, the quality can be trusted, and the most important thing is that we can do better after-sales service. You are welcome to our company.

How should I pay for my order ?

You need to pay 30% as prepayment at first, then we will start to make production. When the machine is completed, we will send pictures / videos to you, and then you need to pay the balance. We will ship the machine to you after we receive your full payment.

How about the machine installation ?

if you need ,we can send engineer to your factory site to help you installation and train your operation engineer.

If you are interested in this product, please fill in the following information and submit it to us, we will arrange professionals to contact us as soon as possible!

Related Products

Related Products

BOXING INDUSTRIAL ZONE,BOXING ,SHANDONG ,CHINA

Hotline:

PRODUCTS