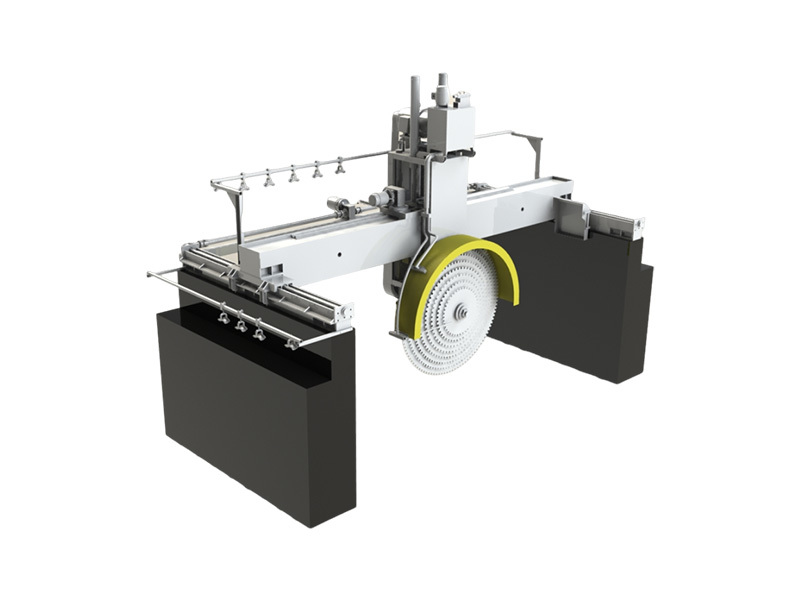

Gantry Combined Stone Cutting Machine (Hydraulic Lifting Type)

Key words:

Gantry Combined Stone Cutting Machine

Gantry Combined Stone Cutting Machine (Hydraulic Lifting Type)

Classification:

Product Description

Equipment introduction

The machine adopts PLC programmable control and human-machine interface, and uses ultra-high precision rotary encoder for slicing. The left and right cutting is controlled by frequency converter, and the speed can be adjusted according to the material of the stone. The up and down lifting adopts hydraulic lifting, combined with the cross-link guide column + wear-resistant guide sleeve, with small matching gap, wear-resistant and beautiful appearance, and multi-layer seals are designed in the guide sleeve to prevent water leakage and oil leakage, and improve the service life. The front and rear slicing adopts high-precision screw nut traditional automatic slicing, and the key parts are all made of wellhead high-quality accessories. The rough material can be cut directly on the ground, saving the trolley and its maintenance costs; therefore, it has the advantages of high cutting efficiency, high slicing accuracy, good flatness of the cut plate, high stability, and easy operation. It is especially suitable for cutting high-value granite and marble rough materials.

Note: If the production process requires, it can be equipped with a 360° rotating workbench.

Technical parameter

|

Model |

DQJ2200A/2500A/2800A |

DQJ2200B/2500B/2800B |

|

Max lifting stroke |

1350mm |

1350mm |

|

Max cutting length |

2800mm/2500mm/2200mm |

3600mm/3300mm/3000mm |

|

Total power |

47-55kw |

55-65kw |

|

Outline dimension |

6900*3800*4200mm |

7800*3800*4200mm |

|

Total weight |

11000kgs |

11500kgs |

- 产品描述

-

- Commodity name: Gantry Combined Stone Cutting Machine (Hydraulic Lifting Type)

The machine adopts PLC programmable control and human-machine interface, and uses ultra-high precision rotary encoder for slicing. The left and right cutting is controlled by frequency converter, and the speed can be adjusted according to the material of the stone.

Equipment introduction

The machine adopts PLC programmable control and human-machine interface, and uses ultra-high precision rotary encoder for slicing. The left and right cutting is controlled by frequency converter, and the speed can be adjusted according to the material of the stone. The up and down lifting adopts hydraulic lifting, combined with the cross-link guide column + wear-resistant guide sleeve, with small matching gap, wear-resistant and beautiful appearance, and multi-layer seals are designed in the guide sleeve to prevent water leakage and oil leakage, and improve the service life. The front and rear slicing adopts high-precision screw nut traditional automatic slicing, and the key parts are all made of wellhead high-quality accessories. The rough material can be cut directly on the ground, saving the trolley and its maintenance costs; therefore, it has the advantages of high cutting efficiency, high slicing accuracy, good flatness of the cut plate, high stability, and easy operation. It is especially suitable for cutting high-value granite and marble rough materials.

Note: If the production process requires, it can be equipped with a 360° rotating workbench.

Technical parameter

Model

DQJ2200A/2500A/2800A

DQJ2200B/2500B/2800B

Max lifting stroke

1350mm

1350mm

Max cutting length

2800mm/2500mm/2200mm

3600mm/3300mm/3000mm

Total power

47-55kw

55-65kw

Outline dimension

6900*3800*4200mm

7800*3800*4200mm

Total weight

11000kgs

11500kgs

Product Video

DLJ220 Cutting Refractory Brick

Equipment working video

Production Equipment

Container shipments

Communication and exchange

FAQ

I need a stone cutting machine , can you give me some suggestions?

Sure, we will give suggestions of the most suitable machine and total solution of whole factory . Before that, we need to know some information, such as stone type, capacity, site condition ,etc., to determine the main parameters.

Which kind of materials can be processed on this machine?

marble B:Granite

Are you a factory or trading company?

We are the manufacturer and we have 10 years factory experience, As the machine made by JUXING factory, the quality can be trusted, and the most important thing is that we can do better after-sales service. You are welcome to our company.

How should I pay for my order ?

You need to pay 30% as prepayment at first, then we will start to make production. When the machine is completed, we will send pictures / videos to you, and then you need to pay the balance. We will ship the machine to you after we receive your full payment.

How about the machine installation ?

if you need ,we can send engineer to your factory site to help you installation and train your operation engineer.

If you are interested in this product, please fill in the following information and submit it to us, we will arrange professionals to contact us as soon as possible!

Related Products

Related Products

BOXING INDUSTRIAL ZONE,BOXING ,SHANDONG ,CHINA

Hotline:

PRODUCTS